And one more thing for OilnH20, did you have an earth anchor pulling them the opposite direction or any kind of tie down? Probably has something to do with them straightening back up?

Shock,

I guess I should have stated it outright - I was relating the experience of rows with angled end posts, but without any earth anchor or bracing. I chose to use what little room I have to get in a couple extra vines, rather than have even shorter rows.

In your first post, you had a question of "do I need the end post angled away..." because of the short run of the row - 60 feet I think you said. My rows are at 42-44 feet long. My holes were hand-dug with a post hole digger - there is no room for equipment in my back-yard because it IS a back-yard, and it's on a slope (and I'd have had to tear down a section of fence at the side of the house to get equipment in anyway, and didn't want to do that).

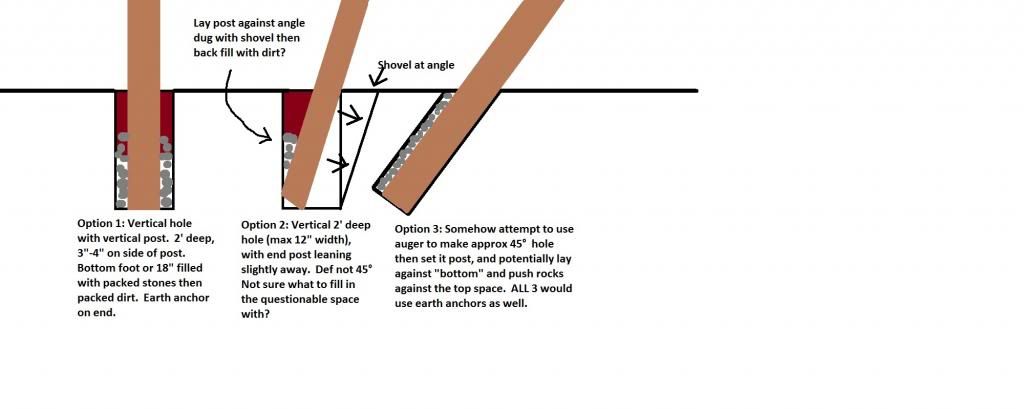

So I angled the posts, holes were 30 inches +/- deep, and then posts angled

across the vertical hole, as you have illustrated as

Option 2 above (but more with a

chamferred top edge rather than the hole dug on an angle all the way to the bottom). Lots of tamping and placement of rocks and cobbles to prevent the post from moving to the vertical, BUT no earth anchor or bracing. Over time (6 years) the posts were pulled to the vertical. AND, I don't think the fact that the wire is tensioned using a turnbuckle or a tensioner tool makes any difference. It is the tensioned wire that is pulling the post from the angle to an upright position. Without tensioning the wire, you will get a lot of droop from the canes and fruit. And, I think if you started at the vertical, it will end up pulling the posts

inward.

Thus, my final sentence in my first post saying I am probably going to have to re-do the end posts (again by hand!) but will put in some sort of earth anchor or brace (because, otherwise, they will continue to be pulled together). But, having said that, the bracing will not be done the proper way simply because I don't have the room.

I hope that makes more sense!