- Joined

- Jan 19, 2018

- Messages

- 314

- Reaction score

- 76

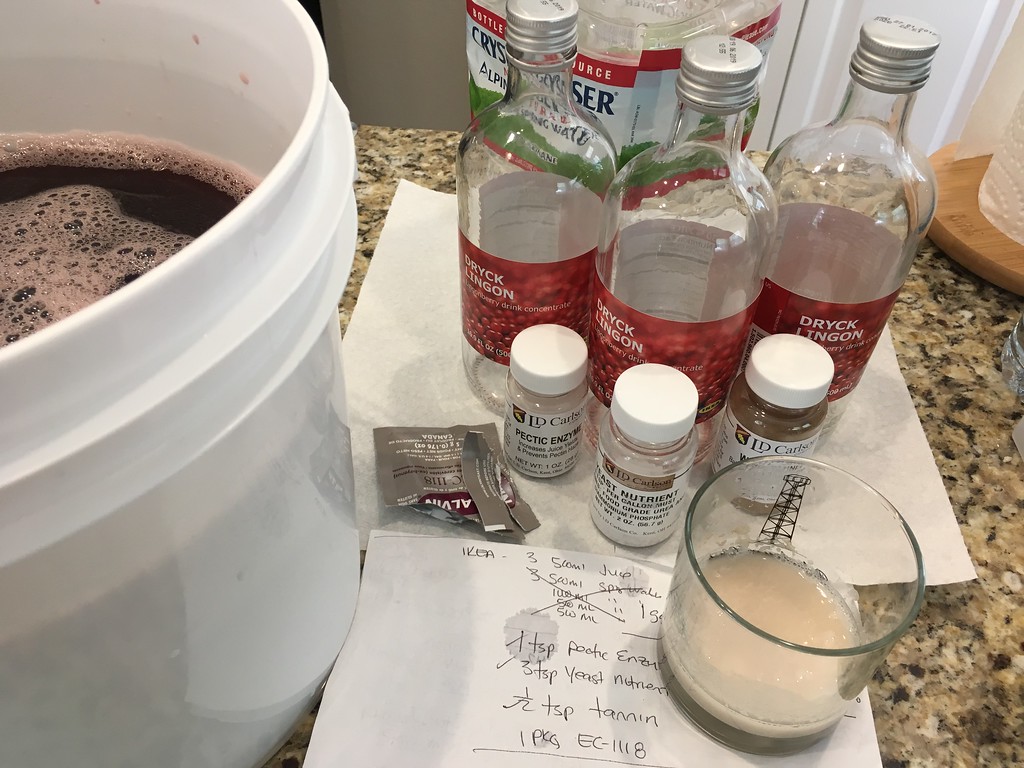

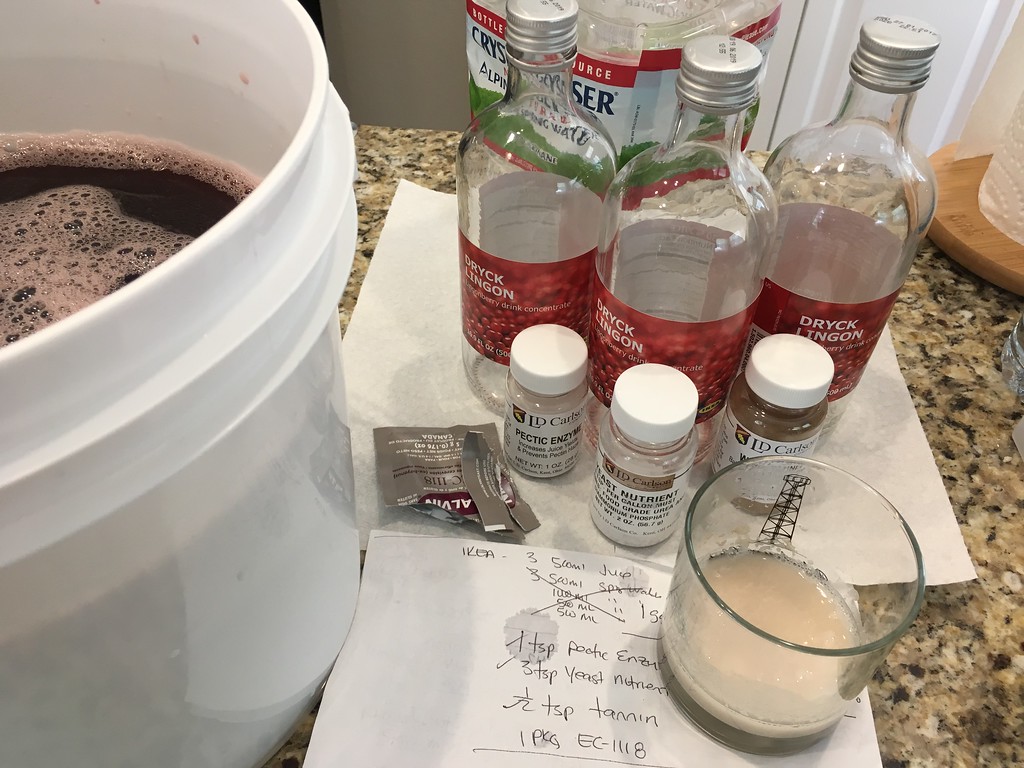

Inspired by sgx2's thread here, I just had to give this a whirl today armed with his instructions and a little bit of knowledge I've learned in such a short time. I have no real expectations for the final product as it just seemed like a fun experiment and a bit of 'cool' factor. That's how I look at it.

Basics include:

3/500ml bottles of IKEA Lingonberry concentrate

1gal Spring Water (that's what it took to get to SG1.087)

1tsp Pectic Enzyme

3tsp Yeast Nutrient

1/2tsp Tannin

1pkg EC-1118

Starting numbers:

SG 1.087

pH 2.7

Acid .60%

I'm going in - wish me luck!

Basics include:

3/500ml bottles of IKEA Lingonberry concentrate

1gal Spring Water (that's what it took to get to SG1.087)

1tsp Pectic Enzyme

3tsp Yeast Nutrient

1/2tsp Tannin

1pkg EC-1118

Starting numbers:

SG 1.087

pH 2.7

Acid .60%

I'm going in - wish me luck!