New_Guy_Brad

Member

- Joined

- Mar 17, 2012

- Messages

- 76

- Reaction score

- 2

I have been reading and it seems some people are using a mix of Red devil tsp/90 and oxy clean free as a cheaper replacement for pbw.

I was going to try this myself, i picked up the oxy clean free and went to a few hardware stores for the red devil tsp/90 only to find none of them carry that brand.

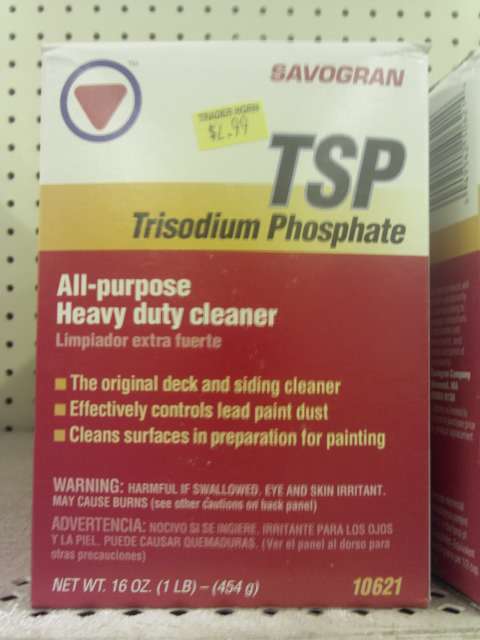

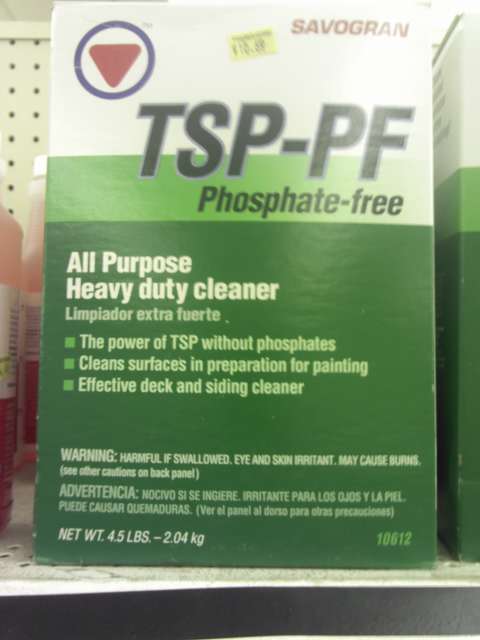

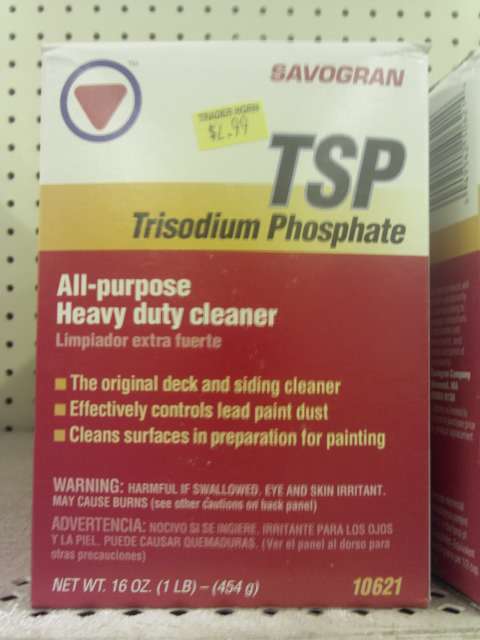

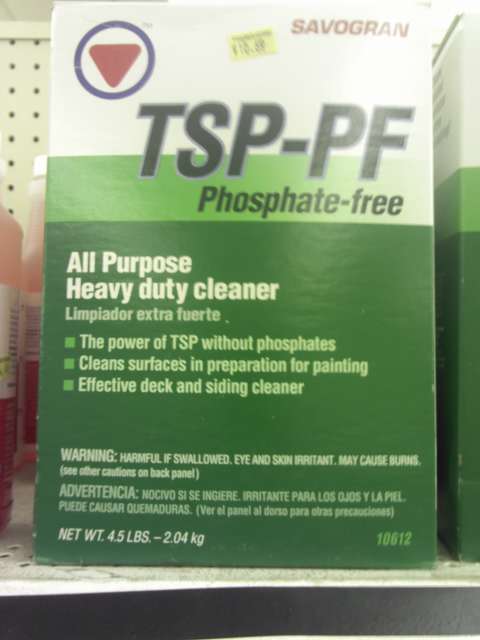

Can i use other tsp products or the other tsp phosphate free instead of the red devil tsp/90 ill post a couple pics below

I was going to try this myself, i picked up the oxy clean free and went to a few hardware stores for the red devil tsp/90 only to find none of them carry that brand.

Can i use other tsp products or the other tsp phosphate free instead of the red devil tsp/90 ill post a couple pics below